Standard Item You Can Choose

| Model | Material | Coating Type | Over size | Positive/Negative | Thickness |

Pattern

|

| LTU-025-(0-9,1)-PG | Quartz Glass | Blue Chrome | 25x25mm/1" | Positive | 1.6mm | Group 0 Element1 to Group 9 Element 1 |

| LTU-025-(0-9,1)-NG> | Quartz Glass | Blue Chrome | 25x25mm/1" | Negative | 1.6mm | Group 0 Element 1 to Group 9 Element 1 |

| LTU-025-(0-9,6)-PG | Quartz Glass | Blue Chrome | 25x25mm/1" | Positive | 1.6mm | Group 0 Element 1 to Group 9 Element 6 |

| LTU-025-(0-9,6)-NG | Quartz Glass | Blue Chrome | 25x25mm/1" | Negative | 1.6mm | Group 0 Element1 to Group 9 Element 6 |

| LTU-050-(0-9,1)-PG | Quartz Glass | Blue Chrome | 50x50mm/2" | Positive> | 1.6mm | Group 0 Element1 to Group 9 Element 1 |

| LTU-050-(0-9,1)-NG | Quartz Glass | Blue Chrome | 50x50mm/2" | Negative | 1.6mm | Group 0 Element1 to Group 9 Element 1 |

| LTU-050-(0-9,6)-PG | Quartz Glass | Blue Chrome | 50x50mm/2" | Positive | 1.6mm | Group 0 Element1 to Group 9 Element 6 |

| LTU-050-(0-9,6)-NG | Quartz Glass | Blue Chrome | 50x50mm/2" | Negative | 1.6mm | Group 0 Element1 to Group 9 Element 6 |

| LTU-076-(-2-9,1)-PG | Quartz Glass | Blue Chrome | 76x76mm/3" | Positive | 1.6mm | Group -2 Element1 to Group 9 Element 1 |

| LTU-076-(-2-9,1)-NG | Quartz Glass | Blue Chrome | 76x76mm/3" | Negative | 1.6mm | Group -2 Element1 to Group 9 Element 1 |

| LTU-076-(-2-9,6)-PG | Quartz Glass | Blue Chrome | 76x76mm/3" | Positive | 1.6mm | Group -2 Element1 to Group 9 Element 6 |

| LTU-076-(-2-9,6)-NG | Quartz Glass | Blue Chrome | 76x76mm/3"> | Negative | 1.6mm | Group -2 Element1 to Group 9 Element1 6 |

| Number of line pairs per millimeter (lp/mm) in USAF Resolving Power Test Target 1951 | ||||||||||||

| Group Number | ||||||||||||

| Element | -2 | -1 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | 0.250 | 0.500 | 1.00 | 2.00 | 4.00 | 8.00 | 16.00 | 32.0 | 64.0 | 128.0 | 256.0 | 512.0 |

| 2 | 0.281 | 0.561 | 1.12 | 2.24 | 4.49 | 8.98 | 17.96 | 35.9 | 71.8 | 143.7 | 287.4 | 574.7 |

| 3 | 0.315 | 0.630 | 1.26 | 2.52 | 5.04 | 10.08 | 20.16 | 40.3 | 80.6 | 161.3 | 322.5 | 645.1 |

| 4 | 0.354 | 0.707 | 1.41 | 2.83 | 5.66 | 11.31 | 22.63 | 45.3 | 90.5 | 181.0 | 362.0 | 724.1 |

| 5 | 0.397 | 0.794 | 1.59 | 3.17 | 6.35 | 12.70 | 25.40 | 50.8 | 101.6 | 203.2 | 406.4 | 812.7 |

| 6 | 0.445 | 0.891 | 1.78 | 3.56 | 7.13 | 14.25 | 28.51 | 57.0 | 114.0 | 228.1 | 456.1 | 912.3 |

| Width of a line in micrometers(μm) in USAF Resolving Power Test Target 1951 | ||||||||||||

| Group Number | ||||||||||||

| Element | -2 | -1 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | 2000.00 | 1000.00 | 500.00 | 250.00 | 125.00 | 62.50 | 31.25 | 15.63 | 7.81 | 3.91 | 1.95 | 0.98 |

| 2 | 1781.80 | 890.90 | 445.45 | 222.72 | 111.36 | 55.68 | 27.84 | 13.92 | 6.96 | 3.48 | 1.74 | 0.87 |

| 3 | 1587.40 | 793.70 | 396.85 | 198.43 | 99.21 | 49.61 | 24.80 | 12.40 | 6.20 | 3.10 | 1.55 | 0.78 |

| 4 | 1414.21 | 707.11 | 353.55 | 176.78 | 88.39 | 44.19 | 22.10 | 11.05 | 5.52 | 2.76 | 1.38 | 0.69 |

| 5 | 1259.92 | 629.96 | 314.98 | 157.49 | 78.75 | 39.37 | 19.69 | 9.84 | 4.92 | 2.46 | 1.23 | 0.62 |

| 6 | 1122.46 | 561.23 | 280.62 | 140.31 | 70.15 | 35.08 | 17.54 | 8.77 | 4.38 | 2.19 | 1.10 | 0.55 |

Specification

| Pattern Info | Substrate Material Info | |||||||

| Production Process | Laser Writing | Substrate Material of Glass | Quartz Glass (Fused Silica) | |||||

| Minimum Line/space | 1μm / 0.55μm | Transmission (@550nm) | >95% | |||||

| Feature Accuracy & Avarage Accuracy | ±1μm | Thermal Expansion Coeff (20-200 ℃) | <5.0x10⁻⁷/K | |||||

| Coating Type | Blue Chrome (Low Reflective) | Expansion Ratio (20-200 ℃) | 0.00006%(0.6μm/℃ of 1m) | |||||

| Reflectivity | < 13.4% @550nm | Surface Flatness | <0.55μm (Dimension<50mm) | |||||

| < 1.8% @650nm | <2μm (Dimension<100mm) | |||||||

| < 2.67% @750nm | <5μm (Dimension>100mm) | |||||||

| Coating Thickness | 120nm (±0.20nm) | Surface Roughness | <0.025μm | |||||

| Optical Density OD | >4.5 | Thickness | 1.6mm (±0.3mm) | |||||

| White Background |

Minimum Line/space: 10μm | MIN / MAX Overall Size |

Min: 4x4 mm; | |||||

| Thickness: 40μm (White & Smooth Coating on the Back Side) | Max: 800x960mm (±0.1mm) | |||||||

| Positive / Negative | Positive: Opaque Pattern, Clear Background. Negative: Clear Pattern, Opaque Background. | Target Shape | Square | |||||

USAF 1951 Test Target Manufacturing: Step-by-Step Production Process

Minimum Line/space

Low Reflectivity Quartz Glass

Key Insight:

Blue Chrome exhibits the lowest reflectivity in the 640-740 nm wavelength range, dropping to nearly 0% reflectivity

Note: Graph shows comparative reflectivity (%) of Bright Chrome, Brown Chrome, and Blue Chrome across 440-1040 nm wavelength range.

Positive / Negative

|

|

| Positive: Dark pattern on transparent background | Negative: Transparent pattern on dark background |

Superior Light Transmission

|

Soda Lime Glass (Float Silica): Transmission Rate >90% at 550nm |

Quartz Glass (Fused Silica): Transmission Rate >95% at 550nm |

Thermal Expansion Coeff

Glass expands when heated and contracts when cooled

Note: Quartz glass offers approximately 14× greater dimensional stability under temperature changes

| Substrate Material of Glass | Soda Lime Glass (Float Glass) | Quartz Glass (Fused Silica) |

| Thermal Expansion Coeff (20-200 ℃) | <8.0x10 -6/K | <5.0x10-7 /K |

| Expansion Ratio (20-200 ℃) | 0.00085% | 0.00006% |

| Real-World Impact | 1m glass changes by 8.5μm per 1°C | 1m glass changes by 0.6μm per 1°C |

| Temperature Stability | Standard stability | 14x more stable |

| Best Applications | General-purpose testing | Precision measurement systems |

Surface Flatness Comparison

Note: Quartz glass consistently delivers 5-10× better surface flatness across all size ranges, making it ideal for precision optical applications.

| Glass Type | Soda Lime Glass (Standard Float Glass) |

Quartz Glass (Fused Silica) |

| Small Samples Surface Deviation |

<5μm (for sizes under 100mm) | <1μm (for sizes under 50mm) |

| Medium Samples Surface Deviation |

<20μm (for sizes under 200mm)

|

<2μm (for sizes under 100mm) |

| Large Samples Surface Deviation |

<50μm (for sizes over 200mm) | <5μm (for sizes over 100mm) |

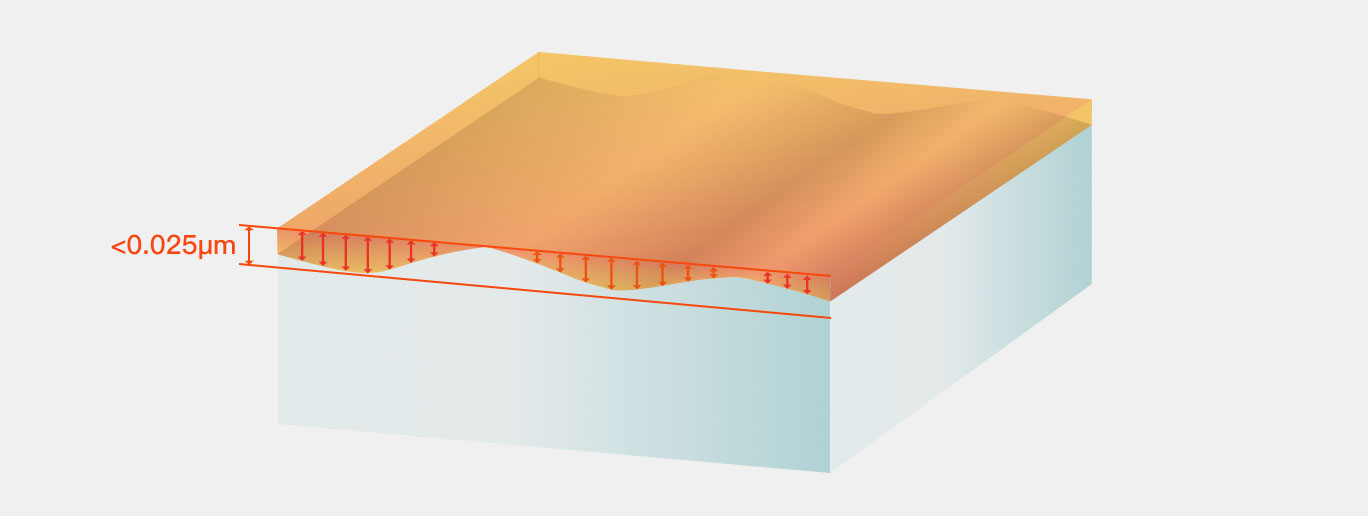

Ultra-Smooth Surface

| Surface Roughness: Less than 25 nanometers |

|

| Note: Diagram shows microscopic surface profile with maximum height variations under 25nm |

Our precision-polished quartz glass features an exceptionally smooth surface with microscopic variations of less than 0.025μm (25nm) - approximately 2,000 times thinner than a human hair.

- Superior optical performance

- Minimal light scatter

- Optimal coating adhesion

- Exceptional image clarity

Diagram shows microscopic surface profile with maximum height variations under 25nm

Precision Thickness Options

Available in multiple thicknesses to suit your application requirements

- 1.6mm - Ultra-thin for compact designs

- 2.3mm - Standard precision applications

- 3.0mm - Enhanced durability

- 4.8mm - Maximum stability for demanding environments

All options feature precision-ground edges and uniform thickness across the entire surface

Dimensional Range

From micro to macro - our quartz glass substrates are available in virtually any size you need:

- Maximum dimensions: 800×960mm

- Minimum dimensions: 4×4mm

Custom sizes and shapes available upon request

Density Measurement

Precision Laser Cutting Custom Shapes Made Easy

From simple to complex designs, our laser cutting technology delivers exactly what you need.

|

| Corner | Chamfer | Hole | Round | Oval |

Custom Services

|

Free CAD Conversion Our engineers will convert your drawings to digital format at no cost. |

Certified Quality Independent third-party certification available upon request. |

No Minimum Order Single-piece orders welcome – no quantity requirements. |

Quick Turnaround Custom production completed in just 5-10 business days. |

Precision Backlighting for Glass Calibration Targets

Our backlighting system features:

- Large illumination area: 2.1 × 1.4 m

- Superior uniformity: 95%

- Dual-spectrum capability: IR and visible light

- High brightness output

- Ultra-slim profile