Our calibration targets are designed specifically for seamless integration with OpenCV and other industry-standard calibration software. The high-contrast patterns are optimized for corner detection algorithms, ensuring fast and accurate calibration results with minimal processing time.

| Standard Model NO. | Substrate Material | Coating Type | Overall Target Size | Active Pattern Area | Checkerboard Pattern | Array | Feature Accuracy |

| LTO-15-0.5-G | Soda Lime Glass | Brown Chrome | 15x15mm | 6x4.5mm | 0.5 x 0.5mm | 9x12 | 1μm |

| LTO-15-0.75-G | Soda Lime Glass | Brown Chrome | 15x15mm | 9x0.75mm | 0.75 x 0.75mm | 9x12 | 1μm |

| LTO-15-1.0-G | Soda Lime Glass | Brown Chrome | 15x15mm | 12x9mm | 1.0 x 1.0mm | 9x12 | 1μm |

| LTO-15-1.5-G | Soda Lime Glass | Brown Chrome | 15x15mm | 18x13.5mm | 1.5 x 1.5mm | 9x12 | 1μm |

| LTO-030-2.0-G | Soda Lime Glass | Brown Chrome | 30x30mm | 26 x 24mm | 2.0 x 2.0mm | 13 x 12 | 1μm |

| LTO-045-3.0-G | Soda Lime Glass | Brown Chrome | 45x45mm | 39 x 36mm | 3.0 x 3.0mm | 13 x 12 | 1μm |

| LTO-060-4.0-G | Soda Lime Glass | Brown Chrome | 60x60mm | 52 x 48mm | 4.0 x 4.0mm | 13 x 12 | 1μm |

| LTO-76-5.0-G | Soda Lime Glass | Brown Chrome | 76x70mm | 65 x 60mm | 5.0 x 5.0mm | 13 x 12 | 1μm |

| LTO-88-6.0-G | Soda Lime Glass | Brown Chrome | 88x88mm | 78 x 72mm | 6.0 x 6.0mm | 13 x 12 | 1μm |

| LTO-111-8.0-G | Soda Lime Glass | Brown Chrome | 111x106mm | 104 x 96mm | 8.0 x 8.0mm | 13 x 12 | 1μm |

|

|

| Product Specification | ||||||||

| Pattern | Substrate Material | |||||||

| Production Process | Laser Writing | Substrate Material of Glass |

Soda Lime Glass (Float Glass) | |||||

| Minimum Feature Size Accuracy(Square/Checker Size/Line Width/Dot) | 1μm/0.7μm | Transmission (@550nm) |

>90% | |||||

| Feature Accuracy Overall Accuracy |

±1μm | Thermal Expansion Coeff (20-200 ℃) |

<80X10⁻⁷/K | |||||

| Coating Type | Bright Chrome (High Reflective) |

Brown Chrome (Usual) |

Blue Chrome (Low Reflective) |

Expansion Ratio (20-200 ℃) |

0.00085% (8.5μm/℃ of 1m) | |||

| Reflectivity | < 66% @550nm | <6% @550nm | < 13.4% @550nm | Surface Flatness | <5μm (Dimension<100mm) | |||

| < 73% @650nm | < 17% @650nm | < 1.8% @650nm | <20μm (Dimension<200mm) | |||||

| < 68% @750nm | < 23% @750nm | < 2.67% @750nm | <50μm (Dimension>200mm) | |||||

| Coating Thickness | 120nm (±0.20nm) |

100nm (±0.20nm) |

120nm (±0.20nm) |

Surface Roughness | <0.025μm | |||

| Optical Density OD | >3 | >3 | >4.5 | Thickness | 1.6mm (±0.3mm) |

2.3mm (±0.3mm) |

3.0mm (±0.3mm) |

4.8mm (±0.3mm) |

| White Background | Minimum Line/space: 10μm, Thickness: 40μm (White & Smooth Coating on the Back Side) |

MIN / MAX Overall Size |

MIN: 4x4mm; MAX: 800x960mm (±0.1mm) |

|||||

| Positive / Negative | Positive: Opaque Pattern, Clear Background. Negative: Clear Pattern, Opaque Background. |

Overall Shape | Any Shape by Laser Cutting |

Square | Oval | Round | ||

| Frosted Glass on the Back | Frosted glass on the back are on request. | Special-shaped | Hole | Chamfer | Angle | Corner | ||

Glass Test Target Manufacturing: Step-by-Step Production Process

Manufacturing Workflow:

|

Step 1: Substrate Material High-quality glass substrate preparation with optical-grade surface finish and flatness specifications. |

Step 2: Laser Writing Precision laser systems create the photoresist pattern with sub-micrometer accuracy, defining the exact checkerboard parttens. |

Step 3: Developing Chemical developing process reveals the exposed photoresist areas, creating the initial pattern structure ready for etching. |

Step 4: Etching Selective etching removes material to create the final high-contrast resolution patterns with sharp, well-defined edges. |

|

Step 5: Pellicle Mounting (Optional) Protective pellicle film installation provides contamination protection while maintaining optical access to the target patterns. |

Step 6: Inspection & Repair Protective pellicle film installation provides contamination protection while maintaining optical access to the target patterns. |

Step 7: Stripping & Cleaning Final photoresist removal and precision cleaning ensures optimal optical performance and long-term stability. |

Step 8: Quality Assurance Final verification testing confirms all specifications meet OpenCV standards with documented traceability and certification. |

Minmum Feature Accuracy | Soda Lime Glass: 1μm

Consistent Mid-Range Reflectivity

Key Insight:

Brown chrome maintains stable 6-30% reflectivity across the 440-1040nm range, providing optimal contrast ratios for reliable corner detection algorithms.

Superior Light Transmission

Soda Lime Glass (Float Silica): Transmission Rate >90% at 550nm

Density Measurement

Optical Density (OD) in soda lime glass refers to the logarithmic measure of light absorption or attenuation as it passes through the glass substrate. It quantifies how effectively the material reduces light transmission at specific wavelengths.

OD Specifications by Application Application

| Application Type | Required OD | Purpose |

|---|---|---|

| Standard Vision | OD 3-4 | General purpose calibration |

| High Precision | OD 4-5 | Sub-pixel accuracy requirements |

| NIR Applications | OD > 4.5 | Near-infrared wavelength optimization |

| Research Grade | OD> 5 | Ultimate contrast for specialized applications |

Thermal Expansion Coeff

Glass expands when heated and contracts when cooled

Note: Quartz glass offers approximately 14× greater dimensional stability under temperature changes

| Substrate Material of Glass | Soda Lime Glass (Float Glass) | Quartz Glass (Fused Silica) |

| Thermal Expansion Coeff (20-200 ℃) | <8.0x10 -6/K | <5.0x10-7 /K |

| Expansion Ratio (20-200 ℃) | 0.00085% | 0.00006% |

| Real-World Impact | 1m glass changes by 8.5μm per 1°C | 1m glass changes by 0.6μm per 1°C |

| Temperature Stability | Standard stability | 14x more stable |

| Best Applications | General-purpose testing | Precision measurement systems |

Surface Flatness Comparison

Note: Quartz glass consistently delivers 5-10× better surface flatness across all size ranges, making it ideal for precision optical applications.

| Glass Type | Soda Lime Glass (Standard Float Glass) |

Quartz Glass (Fused Silica) |

| Small Samples Surface Deviation |

<5μm (for sizes under 100mm) | <1μm (for sizes under 50mm) |

| Medium Samples Surface Deviation |

<20μm (for sizes under 200mm)

|

<2μm (for sizes under 100mm) |

| Large Samples Surface Deviation |

<50μm (for sizes over 200mm) | <5μm (for sizes over 100mm) |

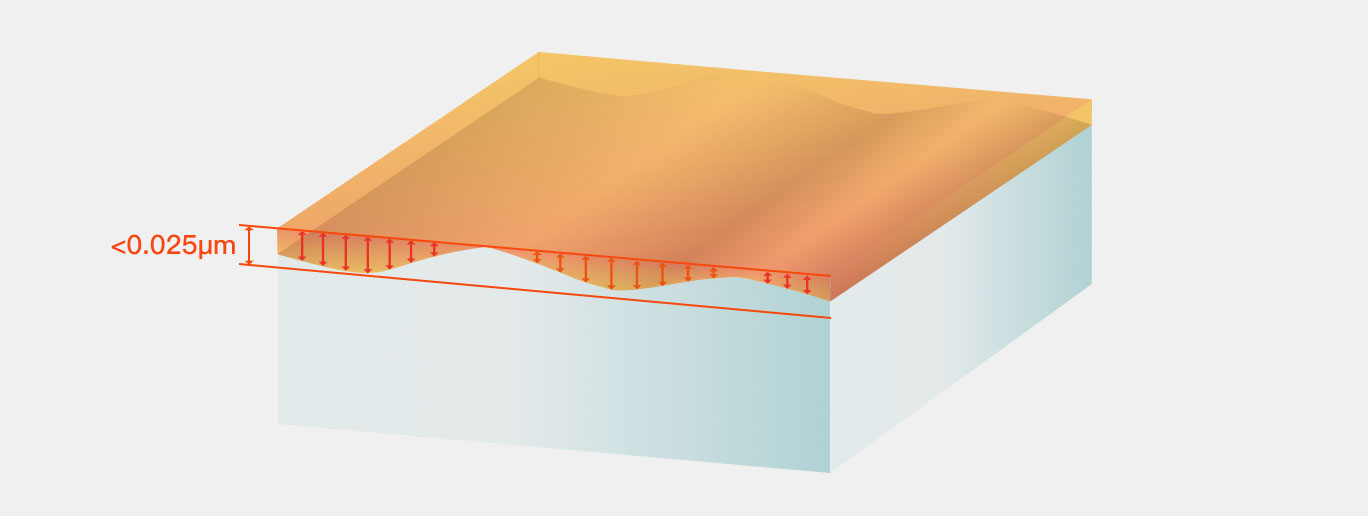

Ultra-Smooth Surface

| Surface Roughness: Less than 25 nanometers |

|

| Note: Diagram shows microscopic surface profile with maximum height variations under 25nm |

Applications Across Industries

These targets are essential for:

Precise industrial measurement systems |

Machine vision quality control |

Robotics and automation |

Medical imaging equipment |

Scientific research |

Autonomous vehicle vision systems |

Customized to Your Exact Specifications

Beyond our standard models, we offer complete customization options:

- Custom Checker Widths: From 0.1mm to 15mm+ to match your optical system

- Flexible Array Patterns: 12×9, 12×13, 15×14, 200×200 and custom configurations

- Edge Distances: Precision-controlled borders from 10mm to 25mm

- Special Requirements: Contact us for unique specifications

Need assistance with your order?

-

Product selection and compatibility

-

Technical specifications

-

Integration with your existing systems

-

Custom requirements for your industry

Don't hesitate to reach out. Technical documentation, integration guidance, and custom solutions are available upon request.

We're committed to ensuring you find the perfect inspection solution for your needs.